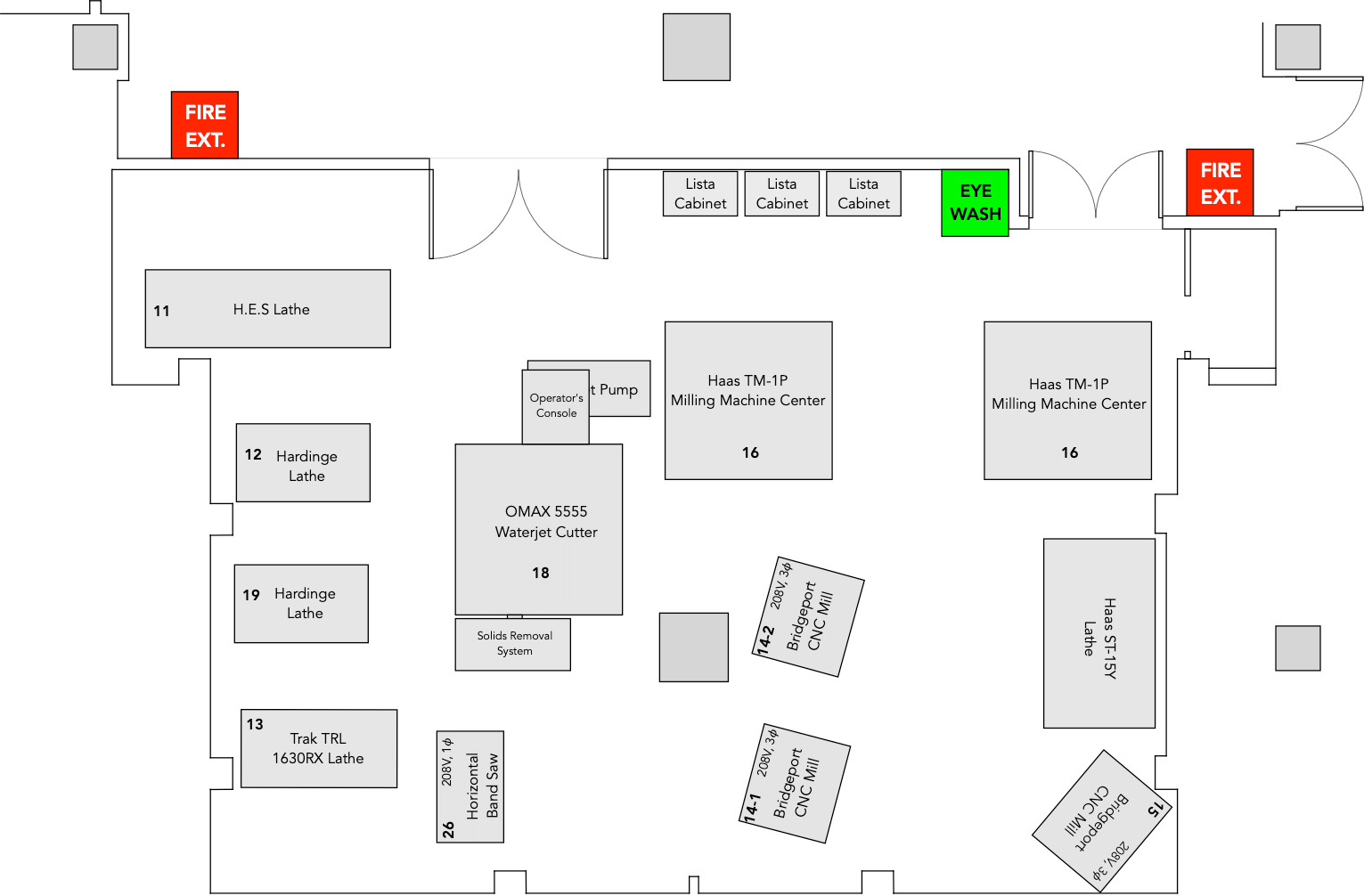

The Baum Family Maker Space machine shop provides a wide variety of machining capabilities to support activities for individual students, class assignments and the needs of the Viterbi competition teams. The machine shop is staffed two full time professional machinists who can fabricate items requested by students, but also provide training to students who wish to learn to use the equipment themselves.

The following describes many of the major pieces of equipment in the machine shop.

Haas VF-2SS Vertical Milling Center

The Baum Family Maker Space has two Haas VF-2SS computer numerical controlled (CNC) milling machine for fully automated 3-axis precision milling. These have a 12,000 RPM spindle speed and an automatic tool changer capable of holding up to 30 different tools. Material is supported on a 36" x 14" table with 30" (X), 16" (Y), 20" (Z) travel. Both mills have a Renishaw tool setter and probe.

Material options:

• Aluminum

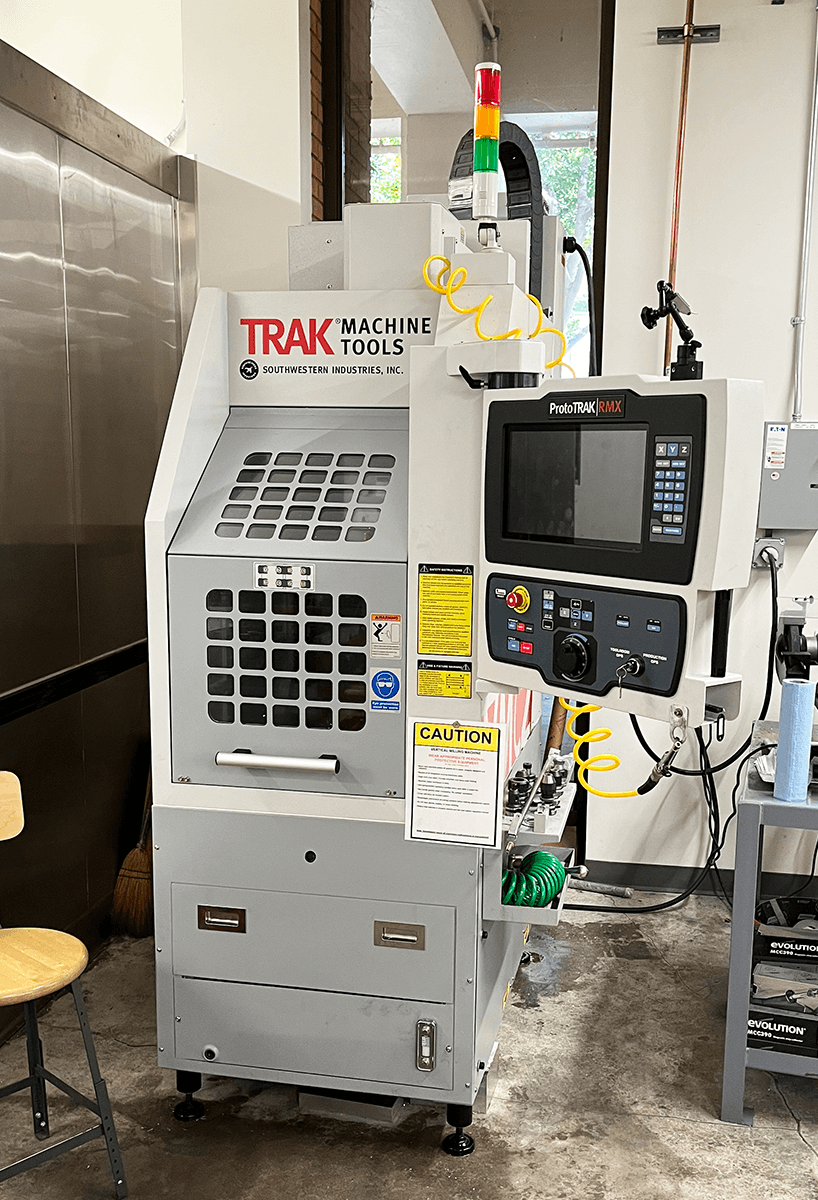

Trak VMC2 Vertical Milling Center

The Trak VMC2 is a computer numerical controlled (CNC) milling machine for fully automated 3-axis precision milling. It has a work volume of 14" x 12" x 17" with 5,000 RPM spindle speed. The VMC2 uses the same ProtoTRAK RMC controls as on the Trak lathe described below and on the Bridgeport lathes that have been upgraded. This makes it easier for students to progress from one of these machines to another.

Material options:

• Aluminum

OMAX 5555 Water Jet Cutter

The OMAX water jet cutting machine uses a very high pressure stream of water to allow rapid, precision cutting in a 2D plane with a cutting envelope of 4'7" by 4'7".

Material optons:

• Steel

• Aluminum

• Stone

• Plastics

• Ceramics & carbides

• Composites & laminates

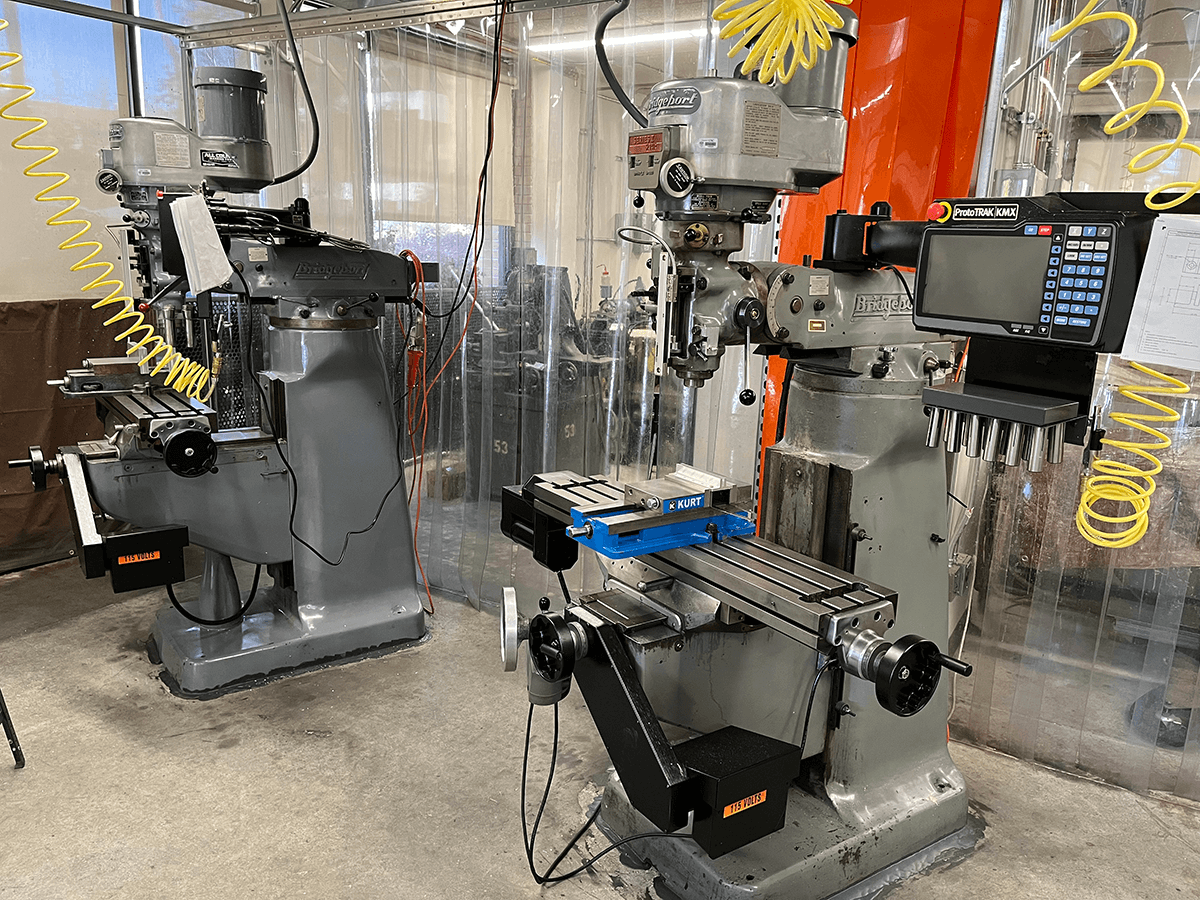

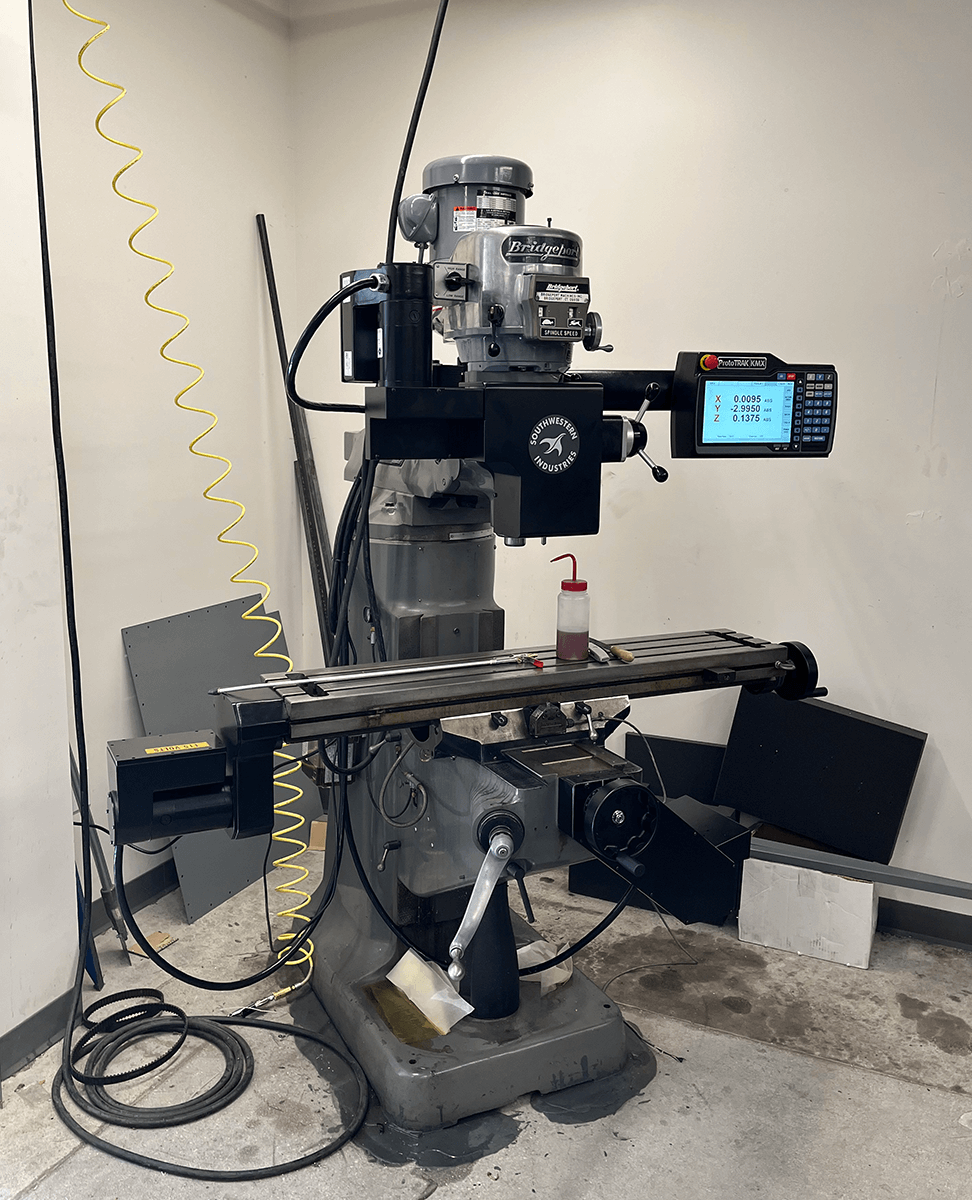

Bridgeport Mill with ProtoTRAK KMX CNC

The Maker Space has two Bridgeport vertical mills, the standard of traditional three-axis milling, retrofitted with CNC capabilities. Both have been upgraded with Trax 2-axis CNC controls.

Material options:

• Steel

• Aluminum

• Brass

• Plastics

• Wood

Bridgeport Vertical Mill with CNC Controls

The Maker Space has a Bridgeport vertical mill retrofitted with Trax 3-axis CNC controls.

Material options:

• Steel

• Aluminum

• Brass

• Plastics

• Wood

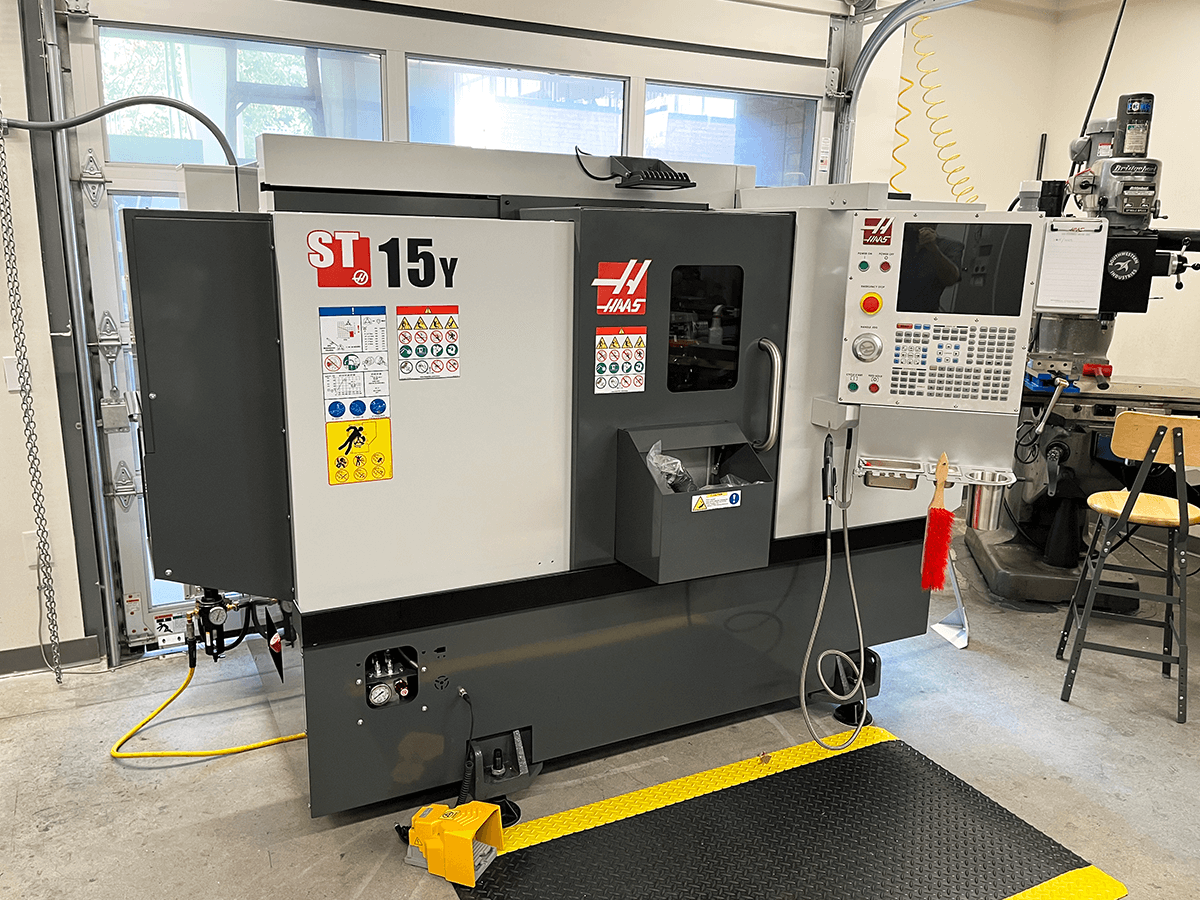

Haas ST-15Y Lathe

The Haas ST-15Y is a CNC (Computer Numerical Control) lathe. It has a 8.3″ chuck with 16.5" swing.

Materiall options:

• Steel

• Aluminum

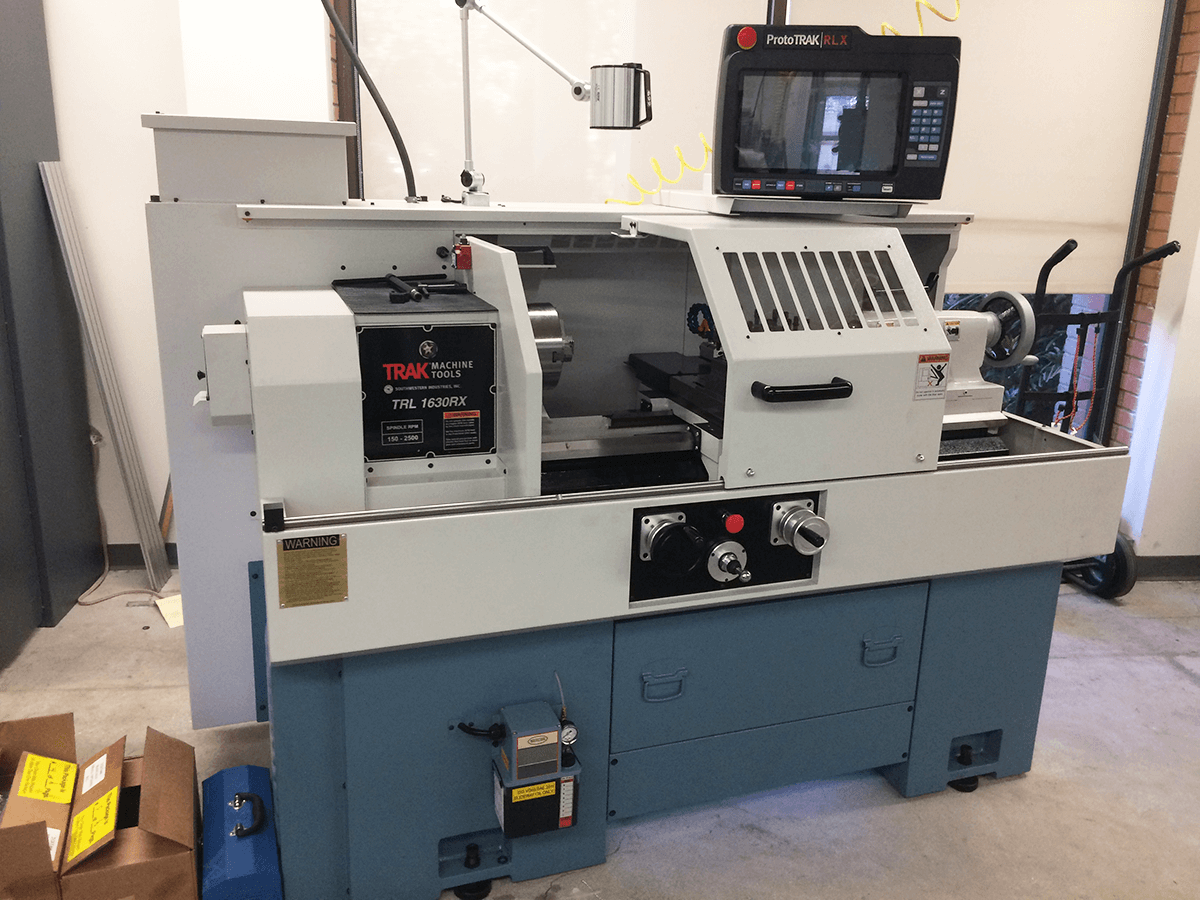

Trax TRL 1630RX Toolroom Lathe

The Trax TRL 1630RX is a CNC (Computer Numerical Control) lathe for 2-axis CNC milling with the option for traditional control. It has a 16″ swing and 30″ between centers.

Materiall options:

• Steel

• Aluminum

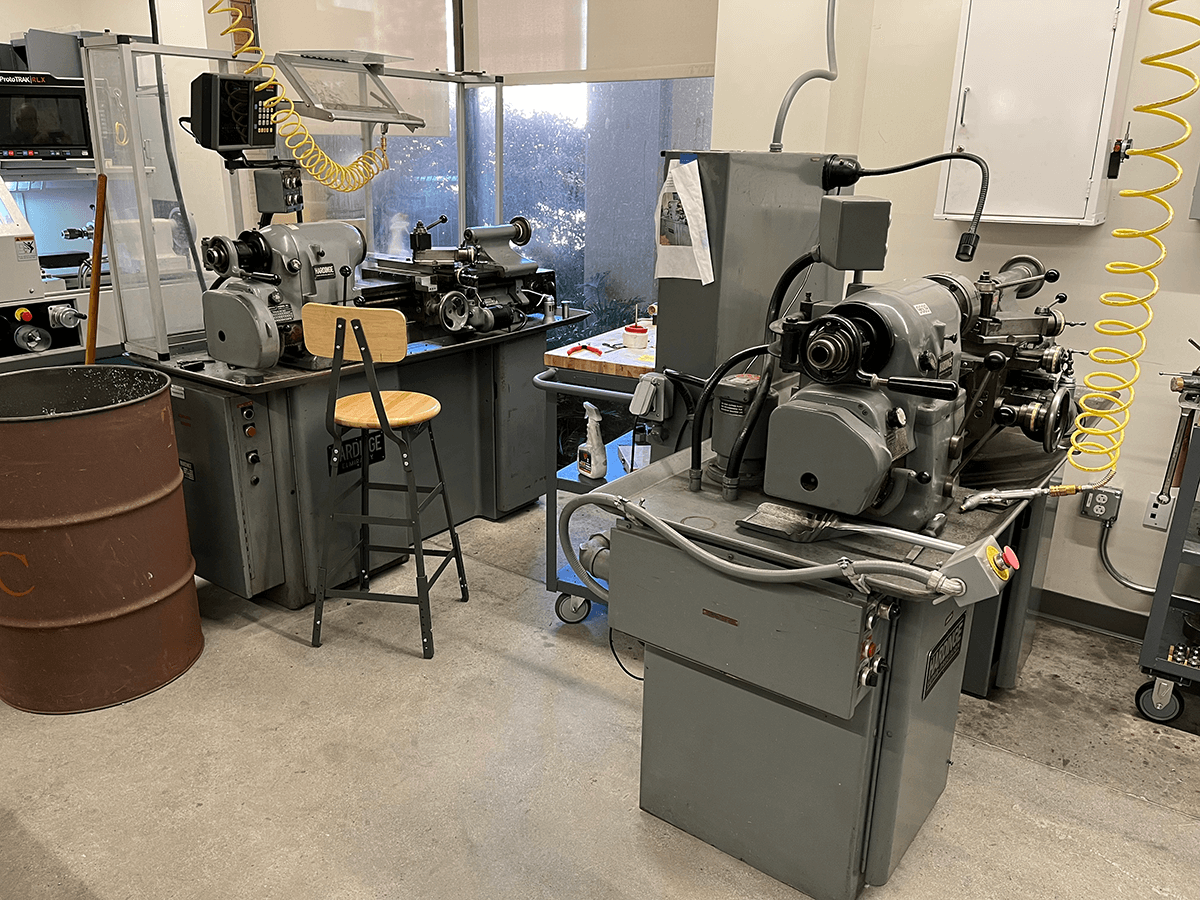

Hardinge Lathe

The two Hardinge lathes are manual lathes for general machining jobs.

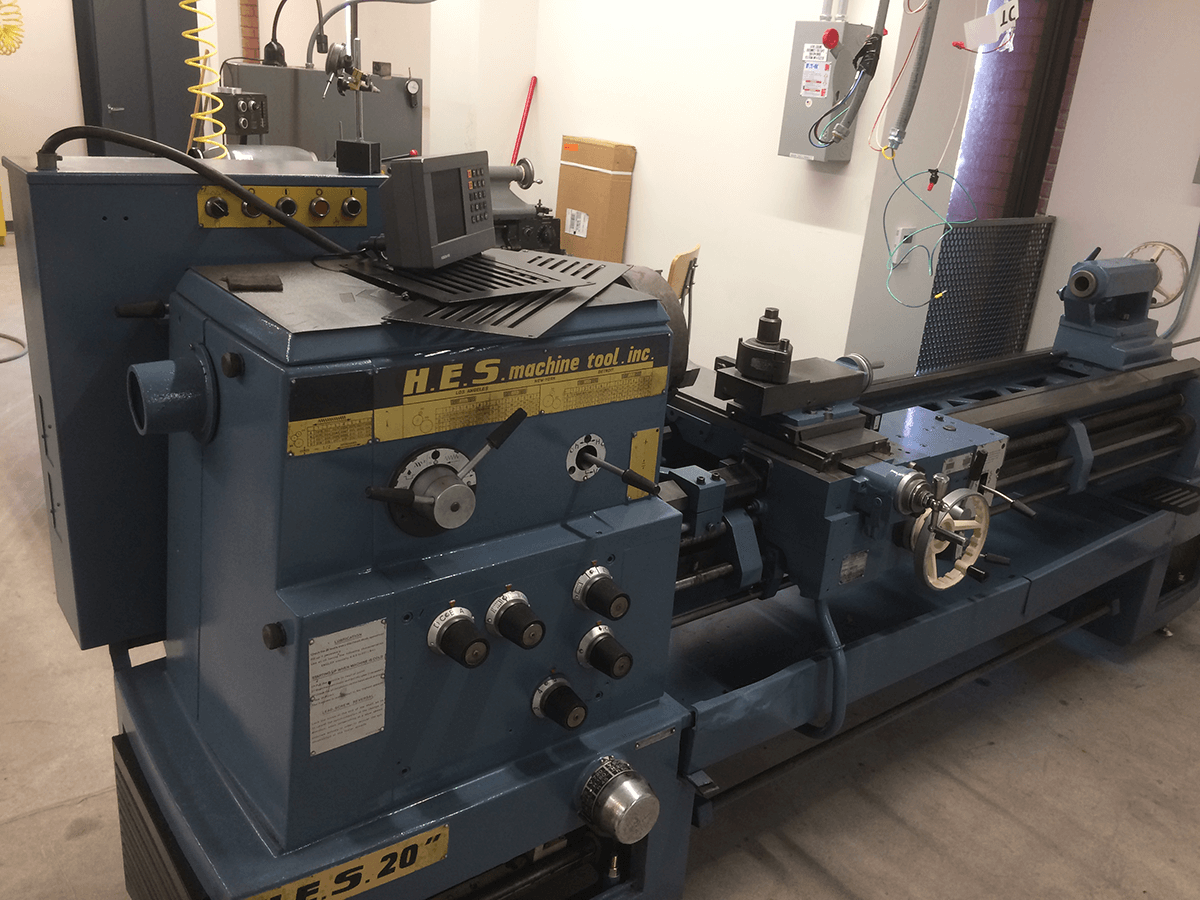

H.E.S. Lathe

The H.E.S. lathe is a French built lathe with a 20" swing, 12 3/8" swing over the cross-slide, and can hold at least a 66" long part. It can thread both metric and Unified Inch Screw Threads. Speed ranges from 36 to 1800 rpm.

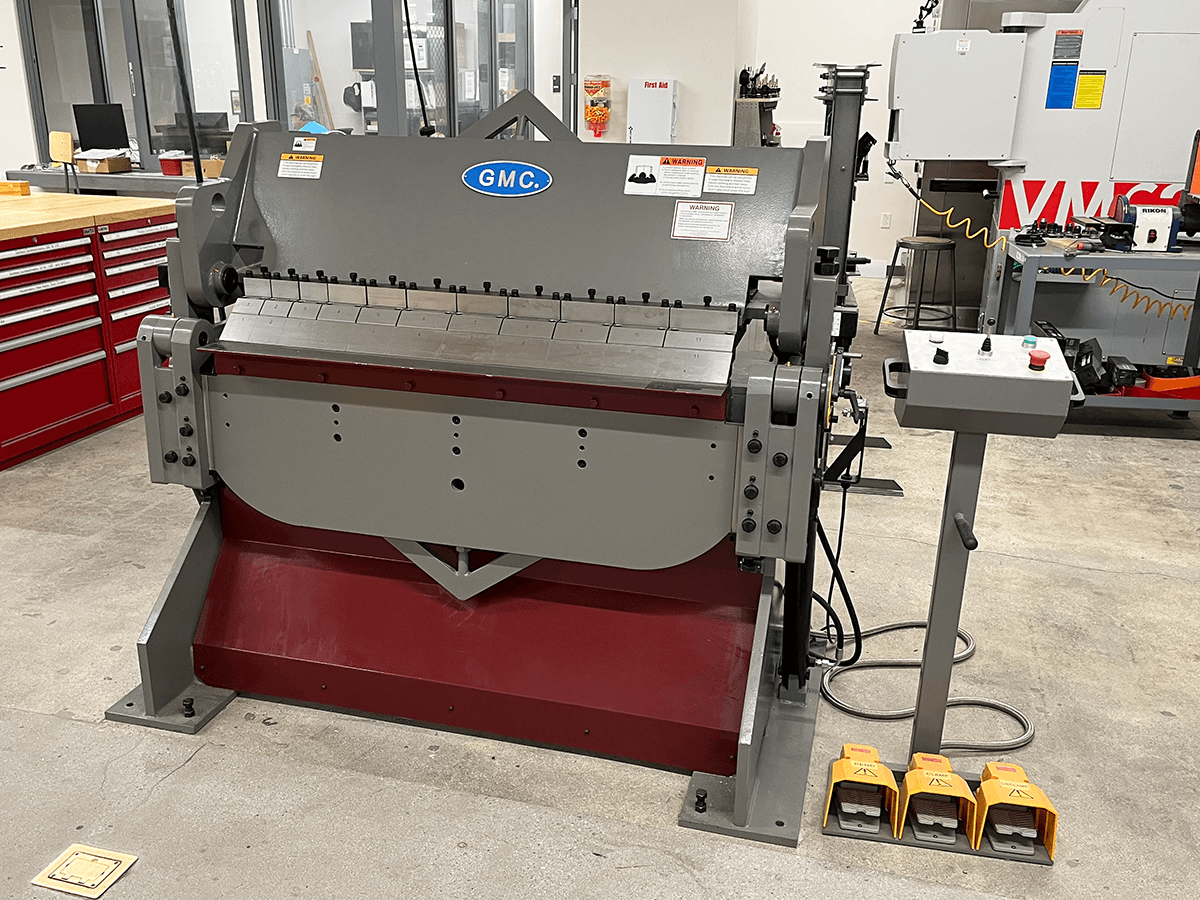

GMC HBB-0410 Sheet Metal Brake

The GMC HBB-0410 is a sheet metal brake for bending metal. With a 4-foot-wide bending area and powered by hydraulics, it can bend steel up to 10 gauge and aluminum up to 1/4” thick.

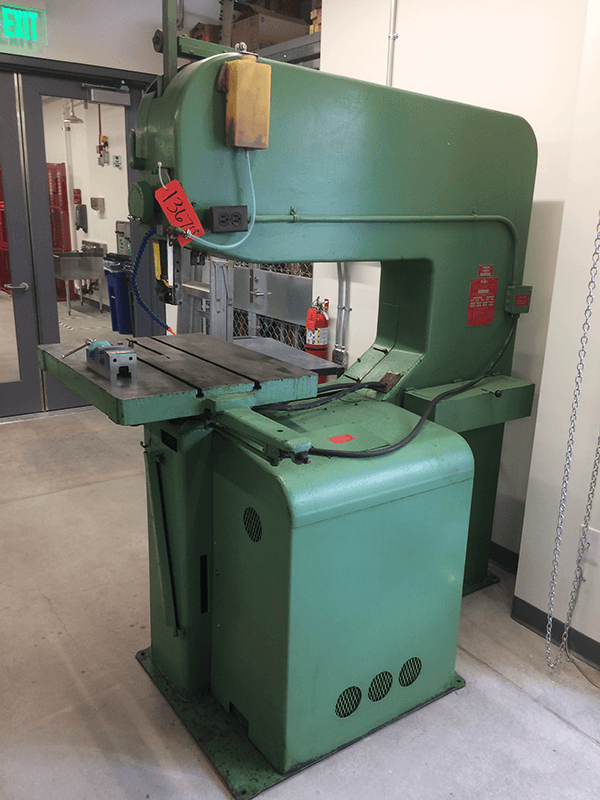

DoAll 3612H Bandsaw

Grizzley Horizontal Bandsaw

The horizonal band saw is used to cut metal and other materials.