The Baum Family Maker Space's Advanced Fabrication Lab is home to a variety of rapid prototyping and manufacturing equipment.

Stratasys F900

The Stratasys F900 is a Fused Deposition Modeling (FDM) 3D printer with a build volume of 36" x 24" x 36". All prints are printed with a secondary, often dissolvable support material.

Material options:

• ABS

• Nylon Carbon Fiber

• ULTEM 1010 Resin

• Polycarbonate

• ASA

• PLA - easy to print, economical, 3D printing go-to plastic

• TPU - rubbery material used to create flexible, impact-absorbent parts

Students are only charged for the cost of the material their printing requires.

Stratasys F370

The Stratasys F370 is a Fused Deposition Modeling (FDM) 3D printer with a build volume of 14" x 10" x 14". All prints are printed with a secondary, often dissolvable support material.

Material options:

• ABS (can be infused with carbon fiber or polycarbonate)

• PLA - easy to print, economical, 3D printing go-to plastic

• TPU - rubbery material used to create flexible, impact-absorbent parts

For printing student work, students are only charged for cost of the material used for their job.

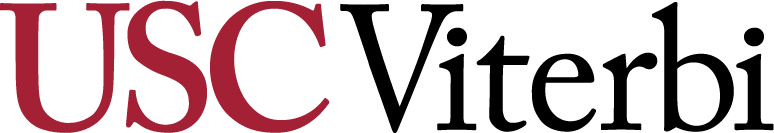

FormLabs Form 3L

The FormLabs Form 3L is a Stereolithography (SLA) Resin 3D Printer with a build volume of 13.2" x 7.9" x 11.8".

Material options:

• Polymer resin - black, white, gray & clear. General purpose, can be brittle.

• Castable wax - purple. Used to create investment molds & cast metal parts.

• Flexible resins - clear. Best for flexible & rubbery parts.

• Polyurethane - black. Strong, impact resistant & pliable.

• High temp & flame retardant resin.

• ESD resin - protects electronics from electrostatic discharge.

• Biomedical resins - designed specifically for medial use.

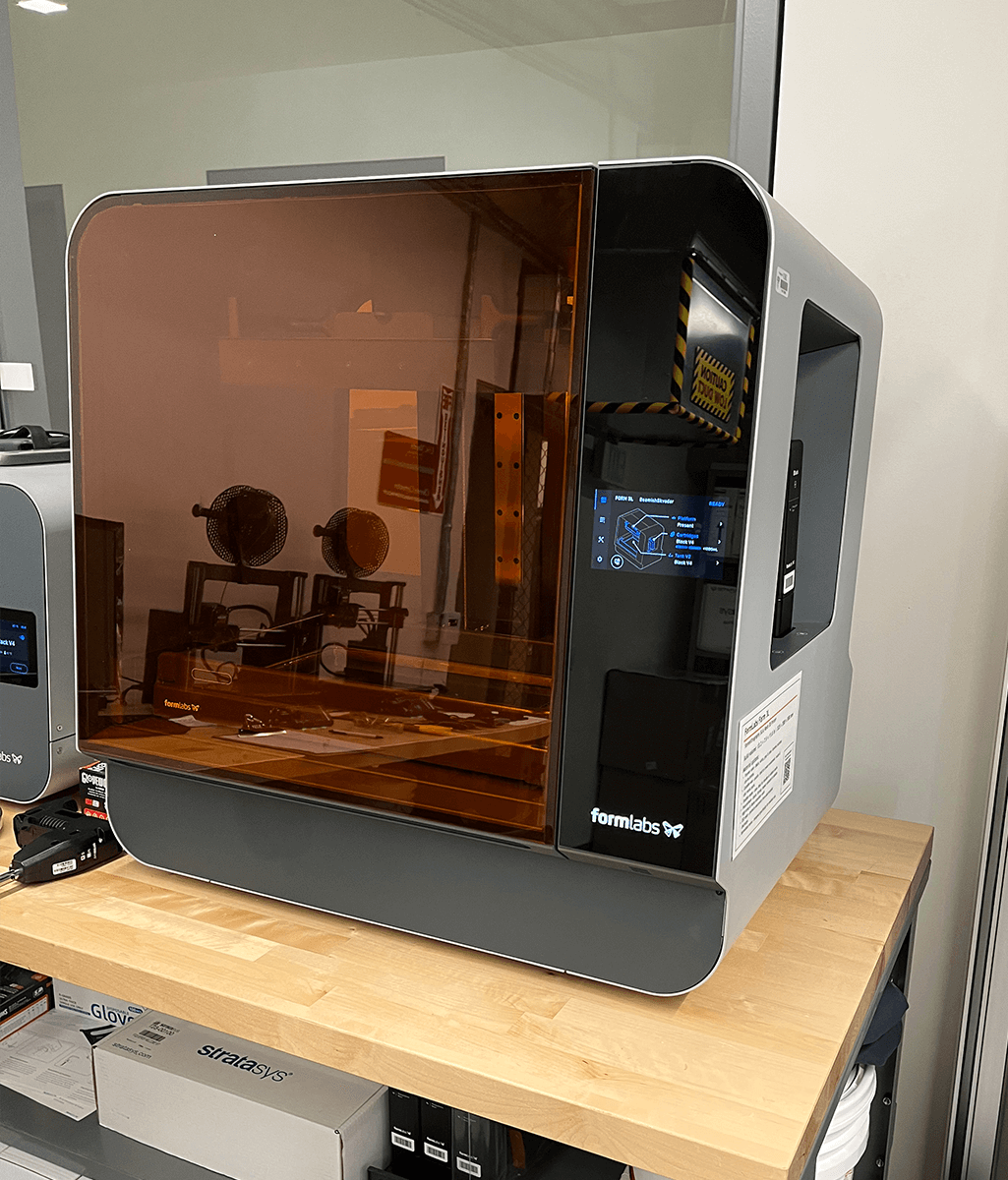

Markforged X7

The Markforged X7 is a Fused Deposition Modeling (FDM) 3D printer with a build volume of 13" x 10.6" x 7.9". This is a Continuous Fiber Reinforcement (CFR) printer, meaning prints can be reinforced with a continuous fiber for increased strength.

Plastic options:

• Onyx - carbon fiber filled nylon

• Nylon - unfilled thermoplastic

• PLA - easy to print, economical, 3D printing go-to plastic

• TPU - rubbery material used to create flexible, impact-absorbent parts

Fiber options:

• Carbon Fiber

• Fiberglass

• Kevlar

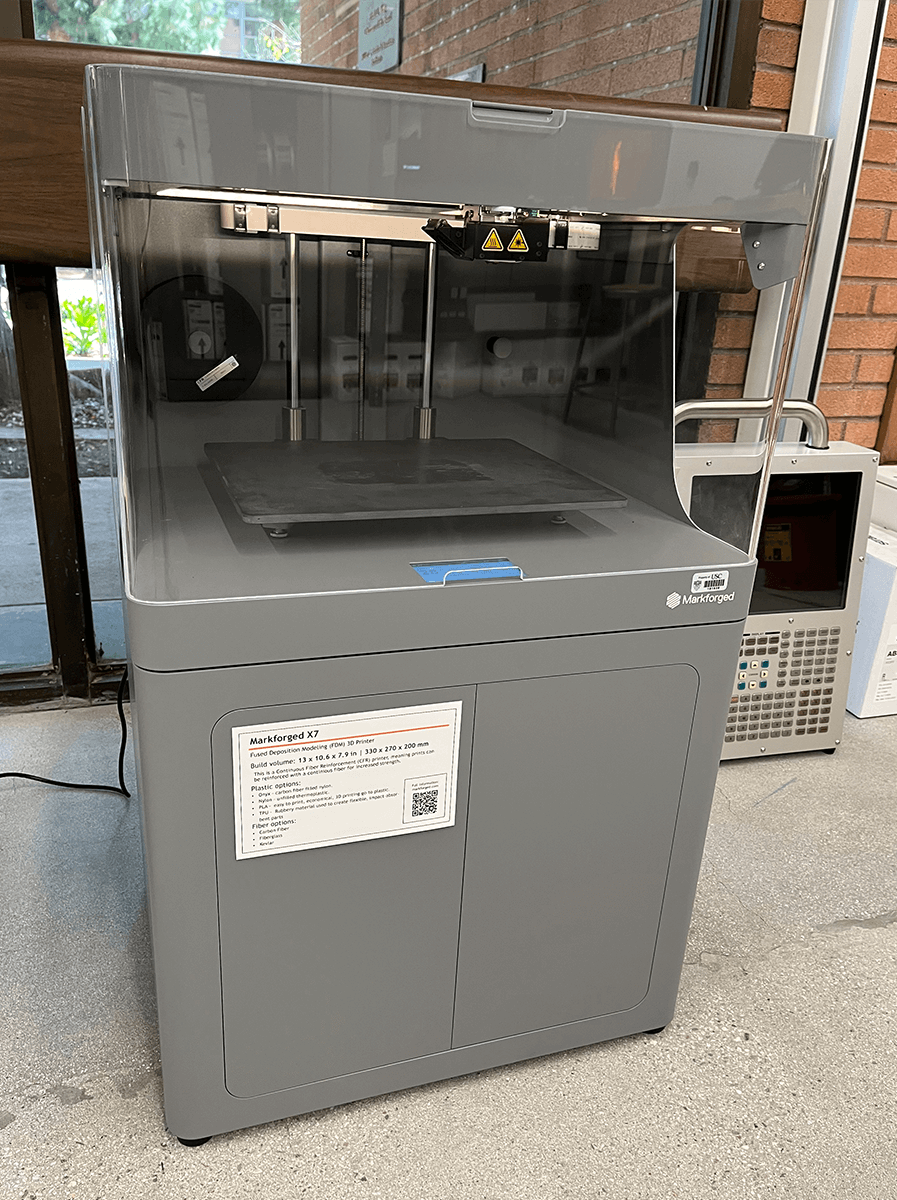

Prusa Pro HT90

The Prusa Pro HT90 is a delta kinematic printer with a cylindrical print volume 15.7" high and a diameter of 11.8". It can print using advanced materials like ABS, ASA, PCCF and PA.

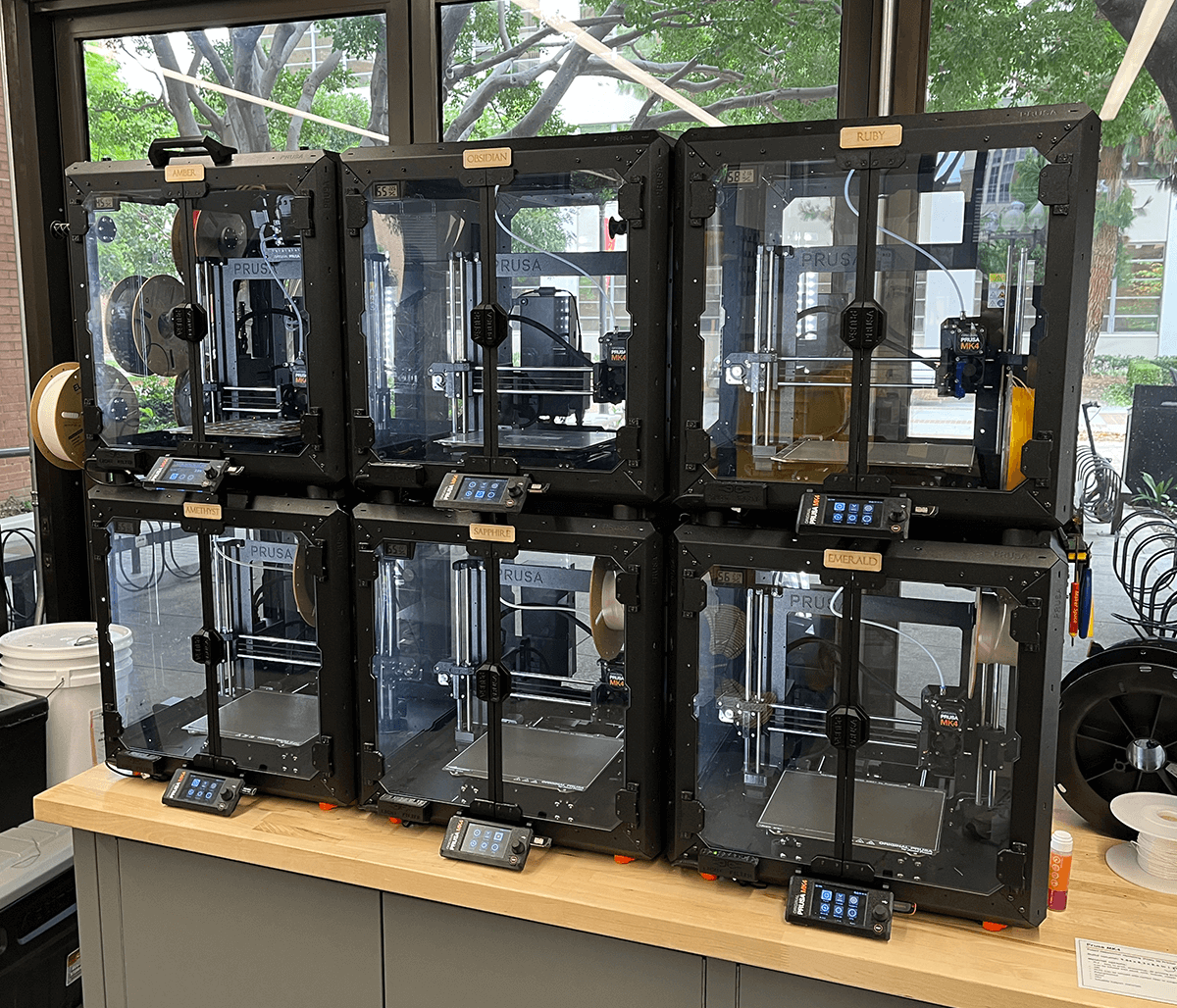

Prusa MK4

The Prusa MK4 is a Fused Deposition Modeling (FDM) 3D printer with a build volume of 9.8" x 8.3" x 8.6". The Maker Space currently has six MK4 printers that are used for general purpose 3D printing.

Material options:

• PLA - easy to print, economical, 3D printing go-to plastic (can be infused with wood, cork, bronze, copper or steel)

• ABS

• PETG (can be infused with carbon fiber or tungsten)

• Polycarbonate

• Nylon

• TPU

• Soluable support material

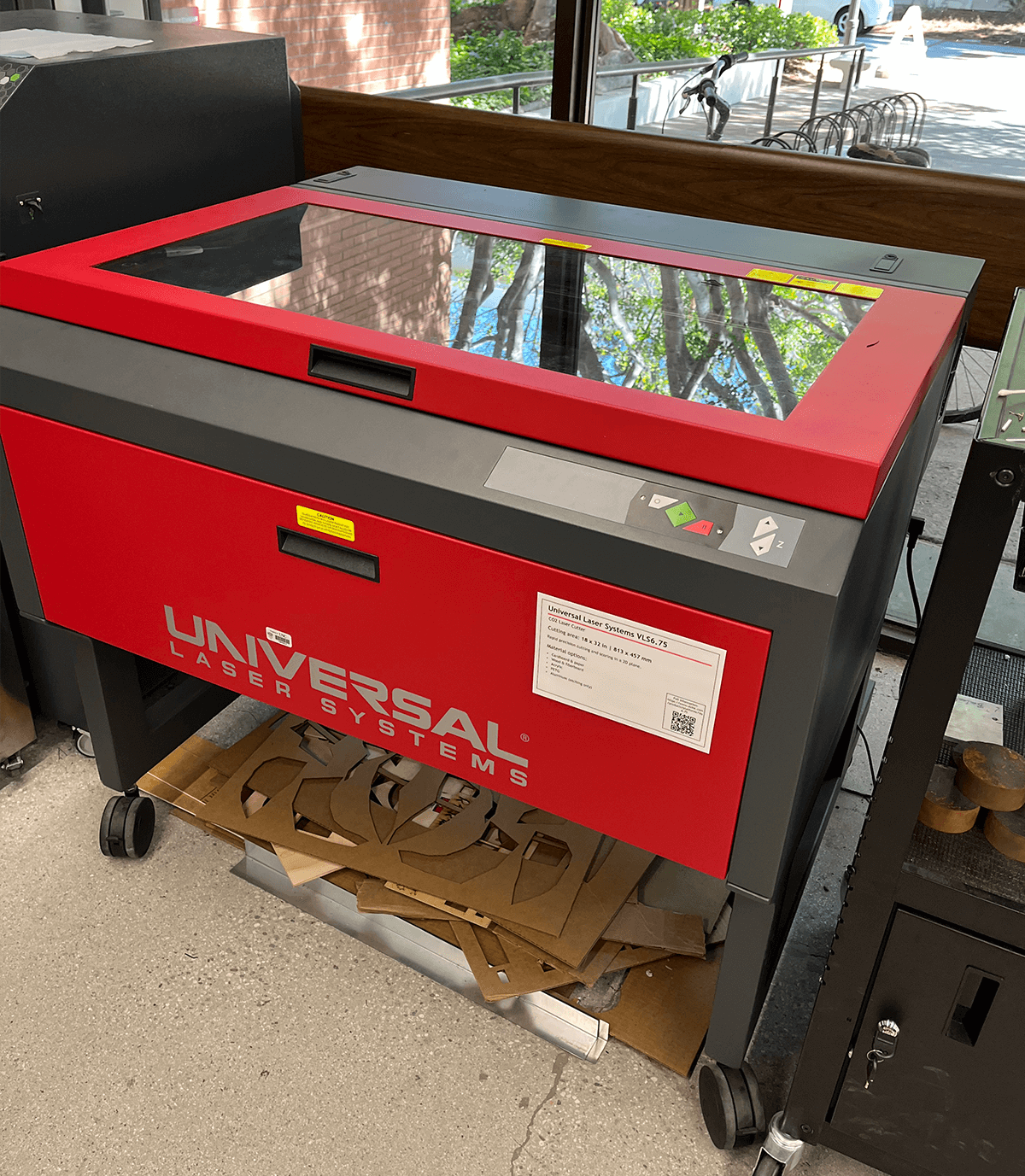

Univeral Laser Systems VLS6.75

The ULS VLS6.75 is a CO2 laser cutter capable of rapid precision cutting and scoring in a 2D plane with a cutting area of 18" x 32".

Material options:

• Cardboard & paper

• Wood and fiberboard

• Acrylic

• PETG

• Aluminum (etching only)

Omegasonics OMG-4030

The OMG-4030 is an ultrasonic cleaner used to remove the support material included in the output from the 3D printers. It has a tank dimensions of 40" x 30" x 40" which is sufficient for the largest output that can be obtained from the 3D printers in the Advanced Fabrication Lab.